General Information

URBAN ROAD PAVEMENT ELEMENTS FACTORY FOR METROPOLITAN CITIES;

It is called for factories that produce all type pavement materials required for all kind of roads and fields necessary for urban in metropolitan cities such as main arterial roads, streets, avenues, site paths, facilities established in side of city ( factories, shopping malls, sport facilities, healthcare fields and etc.), borders, town squares, bazaar places, parks, exhibition grounds and etc.

These are non-sanitary enterprises. While foundation of these enterprises, it is required to take great care in technical features regarding site selection and environmental effects.

Asphalt production plant is the one mostly effecting the environment among these road pavement elements, for this reason considering adverse environmental effects, METROPOLITAN ROAD PAVEMENT ELEMENTS FACTORIES are preferred on the basis of asphalt production.

SİMGE-MAT ASPHALT AND AGGREGATE PRODUCING PLANTS HAVE EXACTLY FEATURE OF «URBAN ROAD PAVEMENT ELEMENTS FACTORY FOR METROPOLITAN CITIES. »

Our plants carry on their activities as complex and integrated facilities with technological competence in the right place at proper production capacity to meet requirements.

Starting from stone quarries, all plants and operations are conducted as efficiently and respectful to the environment.

It is paid attention to visibility states in terms of visual pollution.

IN OUR ALL STONE QUARRIES;

TO MINIMIZE ENVIRONMENTAL IMPACTS OF AGGREGATE PRODUCTION;

- All necessary precautions are taken to minimize dust emission in crushing and screening plants

- All components caused dusting such as crushers, screens and belts are turned into fully closed state.

- Dry type dust filter are used for dust absorbing inside of each components caused dusting.

- Achieved fillers are utilized in asphalt production and as row material in industry.

- Noise level is minimized.

Our asphalt and aggregate productions plants assembled inside of stone quarry in Başköy and Körfez are the optimum plants of which energy loss and dust emission are minimized.

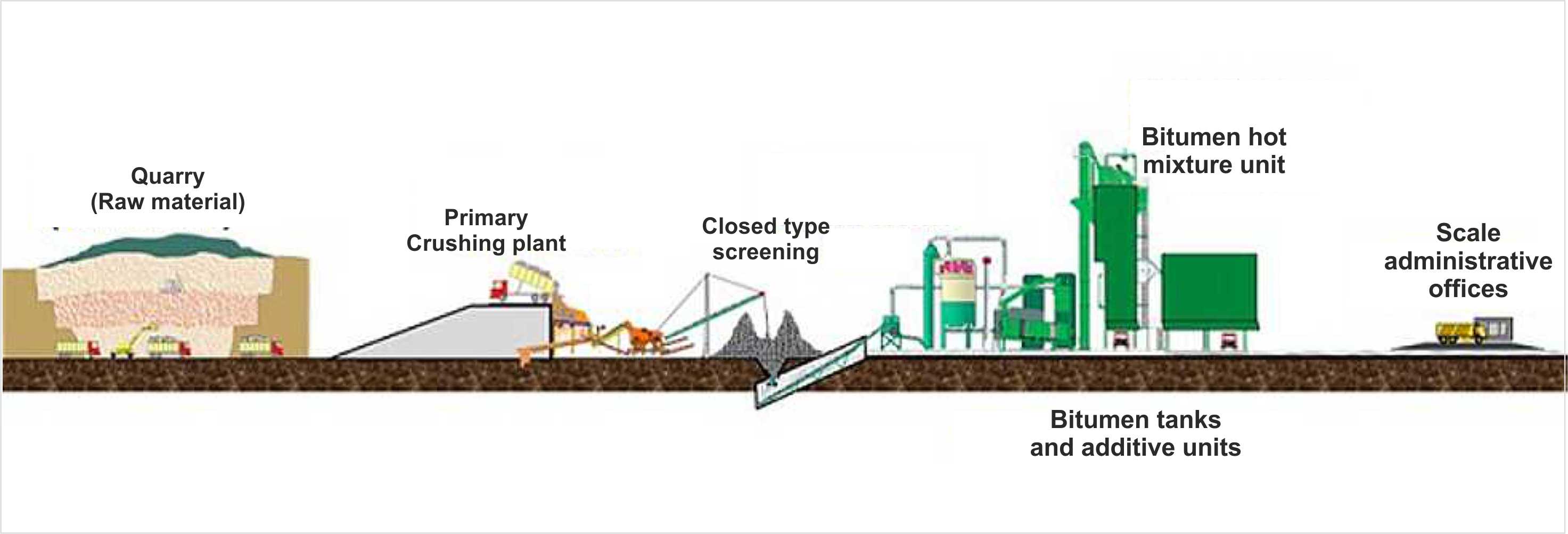

OUR PRODUCTION PROCESS

All process as from feeding achieved raw material from stone quarry to crusher are designed as complex and integrated facilities.

WE CRUSH ASPHALT AGGREGATE IN THE COURSE OF AGGREGATE PRODUCTION.

In our facilities, asphalt and concrete aggregates are not stored outdoor of which grain size below 25 mm, only ballast aggregates are stored in the open field.

Conveyor belts covered and/or operating in a tunnel are used for local transport and feeding the plant instead of using heavy duty equipment and trucks.

Quality loss -caused by storing aggregate in the open field- and economical loss- during feeding of asphalt plant -at conventional aggregate and asphalt productions facilities culminate in using of Simge- Challenger System.

Click for further information about SİMGE CHALLENGER