Production of Road and Superstructure Material

A- BITUMINOUS HOT MIXTURES

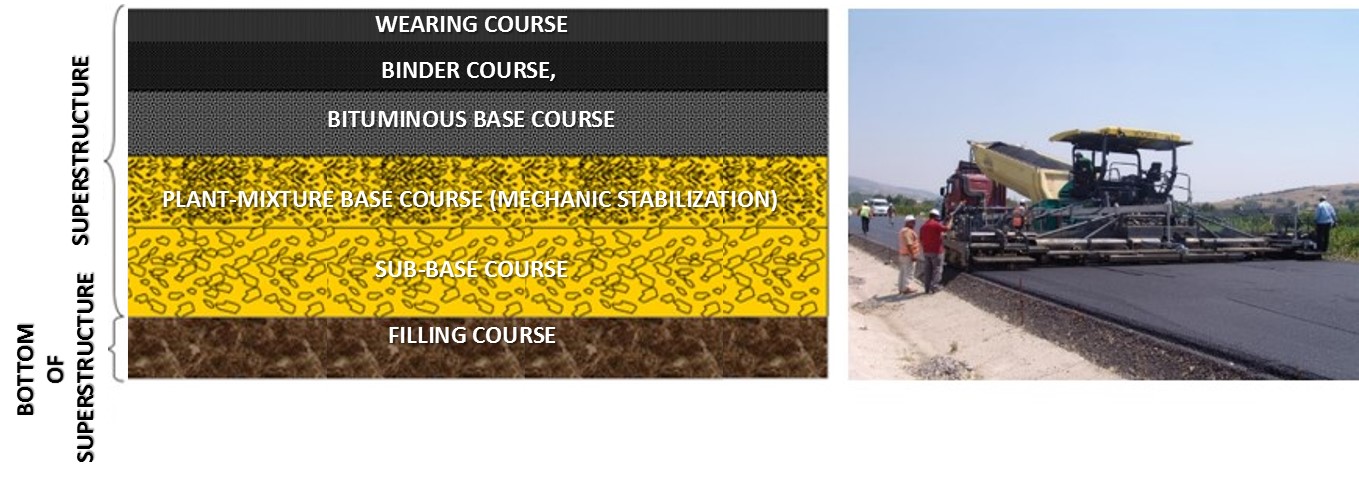

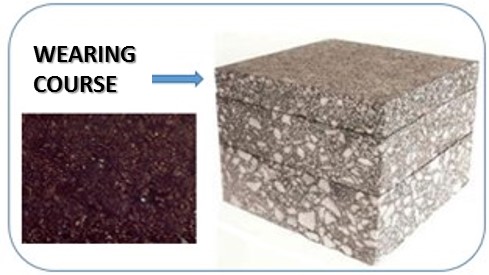

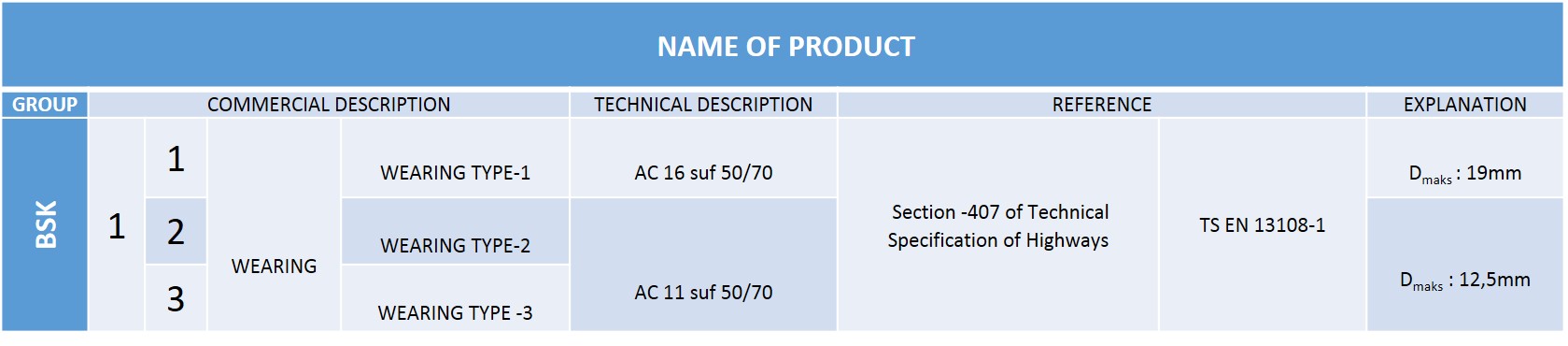

1- ASPHALT CONCRETE – WEARING COURSE

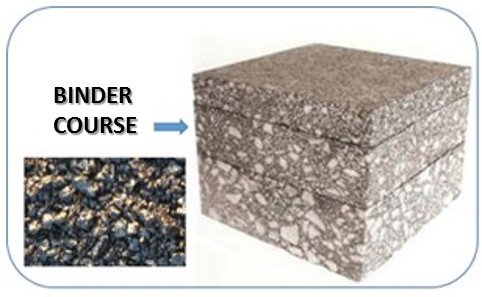

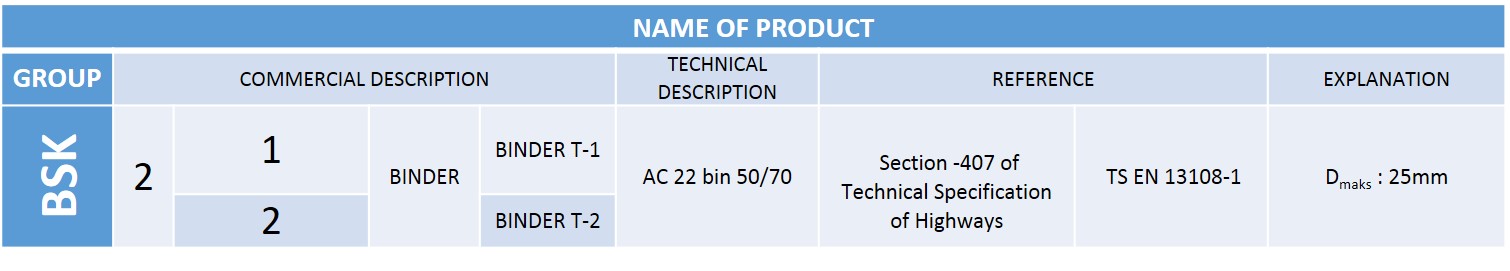

2- ASPHALT CONCRETE – BINDER COURSE

3- BITUMINOUS BASE COURSE

B- BITUMINUOUS COLD MIXTURES

C- BASE, SUB-BASE AND FILLING MATERIALS

1- BASE MATERIALS

1.1- PLANT-MIXTURE BASE MATERIAL

1.2- GRANULAR BASE MATERIAL

2- SUB-BASE MATERIAL

3- FILLING MATERIAL

D- AGGREGATES OF CONCTRETE, ASPHALT, DRENAGE AND SURFACE DREESING

1- CONCRETE AGGREGATES

2- ASPHALT AGGREGATES

3- SURFACE DRESSING AGGREGATES

4- OTHER AGGREGATE PRODUCTS

E- BITUMINOUS MATERIAL AND BINDER MATERIALS

1- MODIFIED BITUMEN

2- CATYONIC BITUMENIOUS EMULTION

A- BITUMINOUS HOT MIXTURES:

High performance of asphalt concrete is possible with good design of the mixture, usage of qualitative raw material and making high standard controlled production and application.

Design of products made of bituminous hot mixture is our own envisagement, asphalt aggregates used as raw material for asphalt concrete production are achieved through Simge-Challenger equipped with special technology.

By means of this, asphalt production with qualified aggregate is implemented. For production of asphalt, controlled production of high standard is implemented by E-MAK branded fully-automatic batch type asphalt plant equipped with high technology.

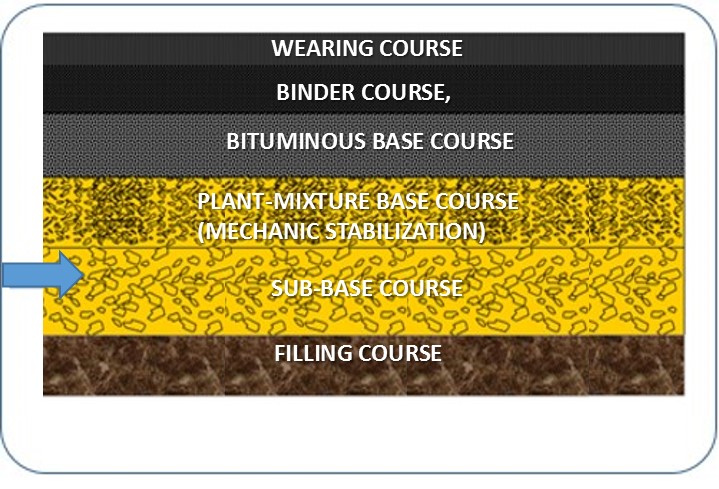

Bituminous pavement courses are in the state of exposed to traffic load and destructive effect of Nature owing to being on the top surface of road. For this reason, our BSK (Bituminous Hot Mixture) products are designed as for long term high performance and produced in high quality.

It is used on roads, airports or other places opened to traffic with adequate (proper) basses or other bituminous pavements on concrete pavements as hot and single course or multiple courses in accordance with plan, profile, and center-section mentioned on its project.

It is durable to carry the loads over it, (having adequate stability). It absorbs expansion arisen from temperature differences. It makes wheel easy rolling. Seal is provided. It provides to controlled flow the water over its surface. It provides adequate smoothness for brake safety. It carries traffic loads and preserves superstructures against deformations. A road surface is achieved with high skid resistance and at the same time giving possibility to drive cozily. It prevents water over road surface to penetrate to the base, sub-base and bottom ground. It is also used in maintenance and repair of deformed and old pavements.

1- ASPHALT CONCRETE – WEARING COURSE

It is produced as listed below in accordance with Section-407 of Highway Technical Specification and TS EN 13108- Standard:

- Wearing Type-1,

- Wearing Type -2 and

- Wearing Type -3

Wearing course- the top surface of superstructure- is generally applied in thickness of 5-6 cm.

2- ASPHALT CONCRETE – BINDER COURSE

It is produced as listed below in accordance with Section-407 of Highway Technical Specification and TS EN 13108- Standard:

- Binder (Type-1) and

- Binder (Type-2)

Binder course applied over bituminous base or granular base is generally applied in thickness of 6-8 cm based on traffic.

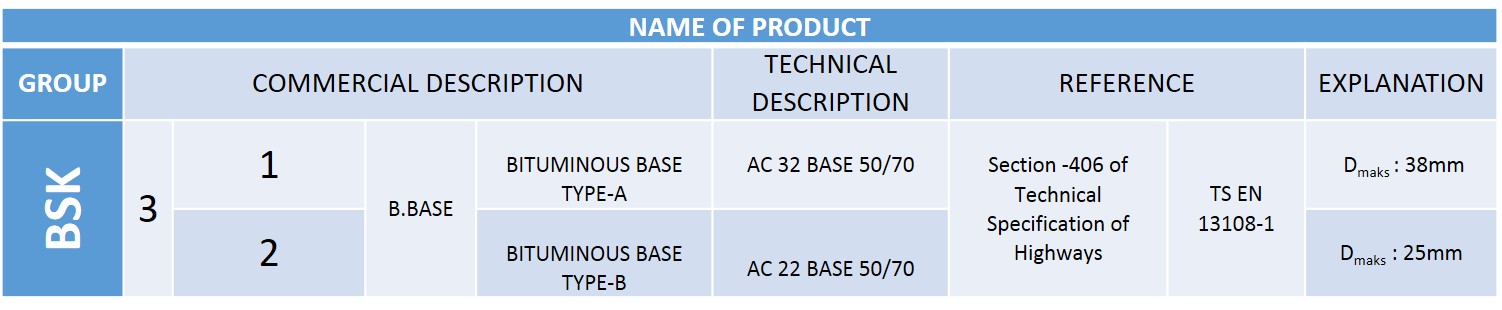

3- BITUMINOUS BASE COURSE

It is produced as listed below in accordance with Section-406 of Highway Technical Specification and TS EN 13108- Standard;

- Bituminous Type-A and

- Bituminous Type -B

Bituminous base course applied generally from 8 cm to12 cm based on traffic is generally a course where bituminous hot mixture is applied over granular base

A- BITUMINOUS COLD MIXTURES:

In accordance with Section-409 of Technical Specifications of Highways, cold mixtures is produced with condition that firstly produced as hot mixture by plant then can be stored and applied as cold only with special additive. Our bituminous cold mixture products are produced in good quality as suitable for using as maintenance material for treatment of road surfaces and as coating in small area with purpose of decoration. It can be stored in places such as open-shed in four months under proper storage conditions

It is delivered in bulk over truck.

It is produced in two type in accordance with form of utilizations:

1- Ready Asphalt

2- Bituminous mixture maintenance material

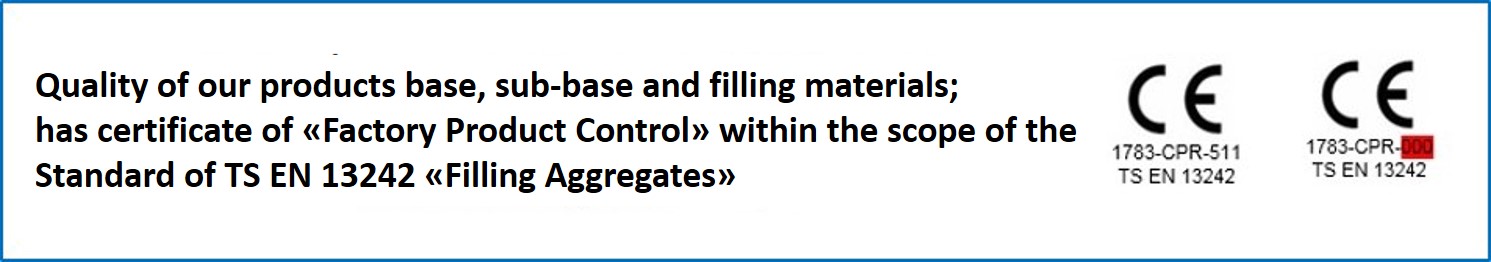

C- BASE, SUB-BASE AND FILLING MATERIAL

1- BASE MATERIALS

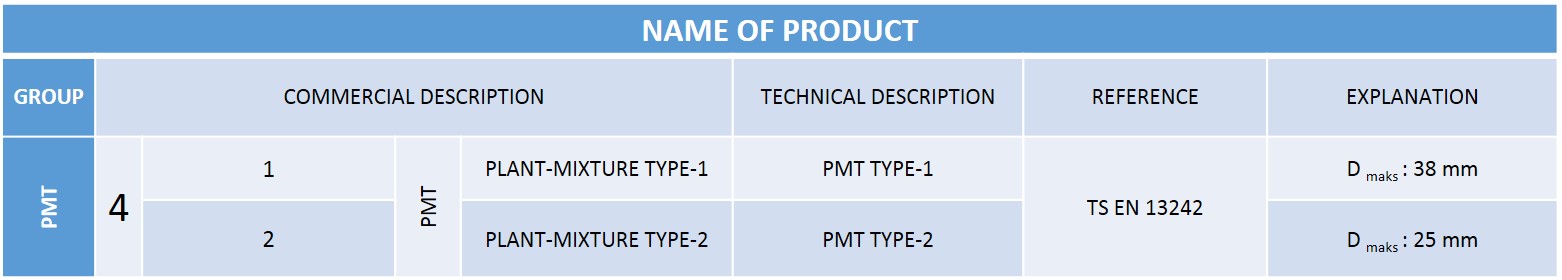

- 1. PLANT-MIXTURE BASE MATERIAL

Road plant-mixture base material is kind of material that used in structuring plant-mixture base coat of road body, obtained by putting it through primary crushing and sieving, prepared through mixing aggregates from at least three particule classes mixed with water at definite proportion by mechanical plant and it is spread by finisher on road.

In accordance with Section-402.04 of Technical Specification of Highways and the Standard of TS EN 13242, it is produced as

- PMT Type-1 and

- PMT Type-2

It is obtained from mixing at least three different kind of aggregate groups in proper quality as defined proportions with optimum water content by E-MAK branded automatic Mechanic Stabilization Plants.

Transported as moist to application area, spread as definite grades by finisher and compressed.

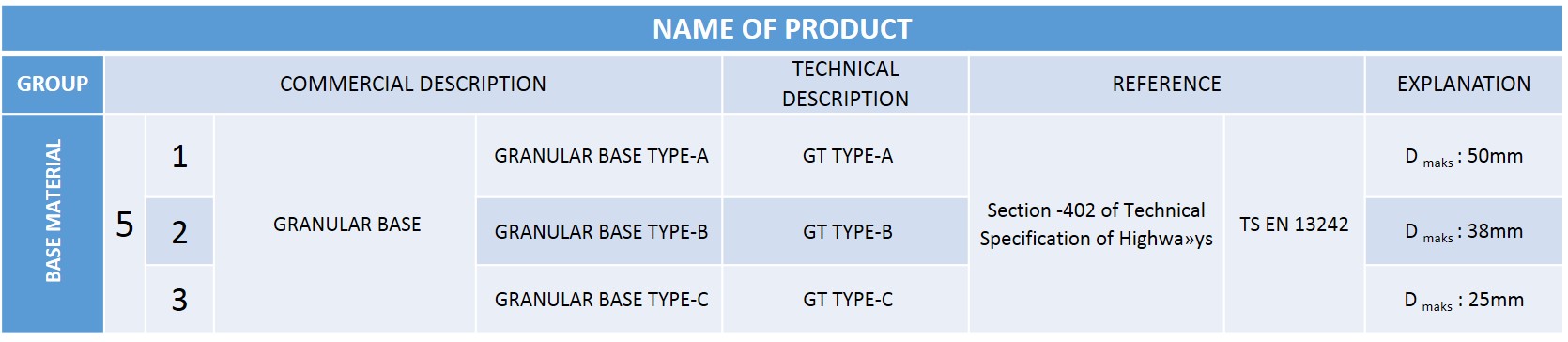

- 2. GRANULAR BASE MATERIAL

Road base material is a kind of material that used in structuring base coat of road body, obtained by putting it through primary crushing and sieving, prepared through mixing with water at definite proportion in specific qualities and granulation.

In accordance with Section-402.03 of Technical Specification of Highways and the Standard of TS EN 13242, it is produced as

- GT Type-A,

- GT Type-B and

- GT Type-C

In production of it, kind of materials are used that obtained from mixing water in suitable proportion with aggregate material prepared in proper quality within the border of required grading limits as providing continuous gradation.

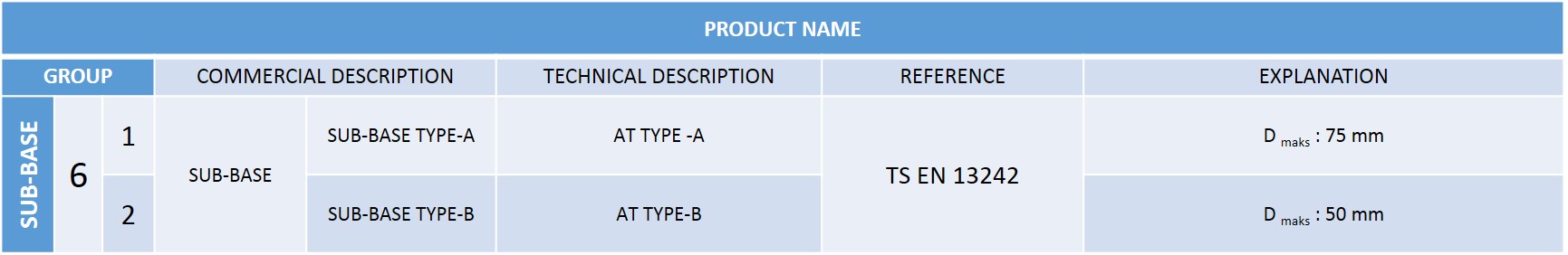

2- SUB-BASE MATERIAL

Road sub-base material is a kind of material in specific qualities and granulation that used in structuring sub-base coat of road body, obtained by putting it through primary crushing and sieving.

In accordance with Section-401 of Technical Specification of Highways and the Standard of TS EN 13242, it is produced as

- AT Type-A and

- AT Type-B

In production of it, kind of materials are used that obtained from mixing water in suitable proportion with aggregate material prepared in proper quality within the border of required grading limits as providing continuous gradation.

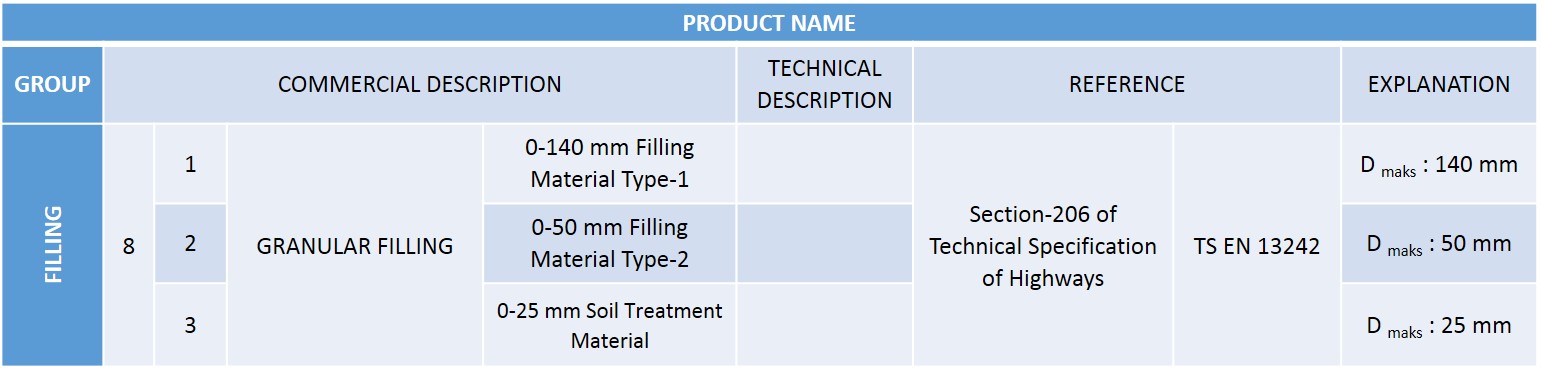

3- FILLING MATERIALS

Filling and soil amendment materials are kind of materials that obtained from raw material or obtained by putting raw material through primary crushing.

In accordance with Section-206 of Technical Specification of Highways and the Standard of TS EN 13242, it is produced as

- 0-140 mm FILLING Material Type-1,

- 0-50 mm FILLING Material Type -2 and

- 0-25 mm SOIL AMENDMENT MATERIAL Type

In production of it, kind of materials are used that obtained from mixing water in suitable proportion with aggregate material prepared in proper quality within the border of required grading limits as providing continuous gradation.

D- AGGREGATES OF CONCRETE, ASPHALT, DRAINAGE AND SURFACE TREATMENT

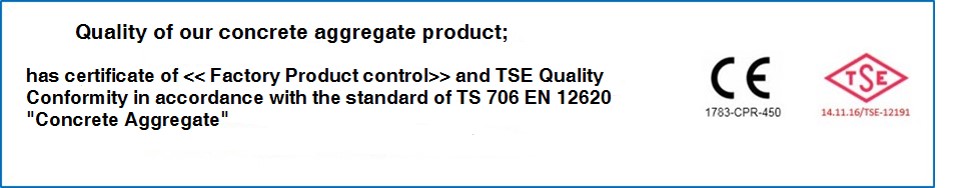

1- AGGREGATES OF CONCRETE

Our concrete aggregate products are produced of high quality by Simge Challenger, special production of E-MAK, in accordance with the standard of TS 706 EN 12620 with the purpose of increasing the quality of concrete for which it will used and by means of the system it is delivered to our costumer as moisture free and without any quality loss. Concrete aggregate is produced in particularly four different particule-size distribution:

- 0/4 mm for special performance concrete

- 0/4 mm,

- 4/11 mm and

- 11/22 mm

SPECIAL PRODUCTION FINE CONCRETE AGGREGATE FOR PERFORMANCE CONCRETE 0-4 mm:

Fine concrete aggregate is produced as 0-4mm in ideal gradation and fineness produced specially for performance concrete and precast products in accordance with the standard of TS 706 EN 12620.

It is produced by special type Simge Challenger system, designed for production of fine aggregate only with specified class and features by means of the system it is delivered to our costumer as moisture free and without any quality loss.

Very fine material amount in fine aggregate content can be categorized by means of the System.

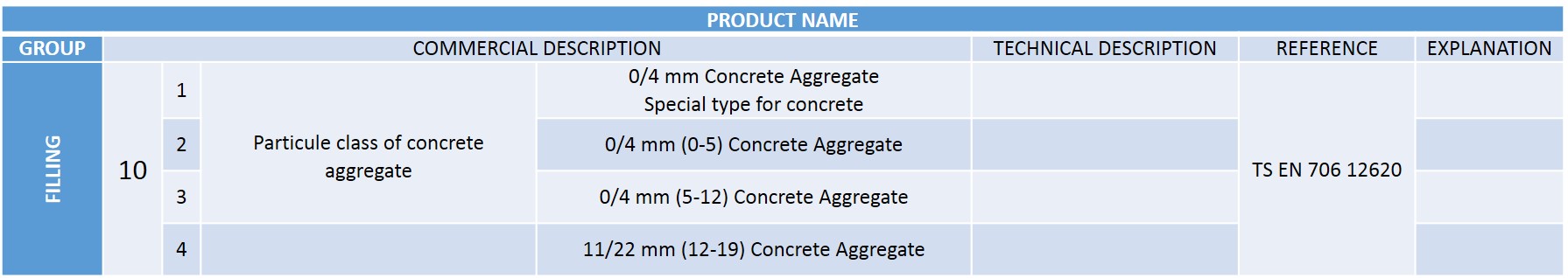

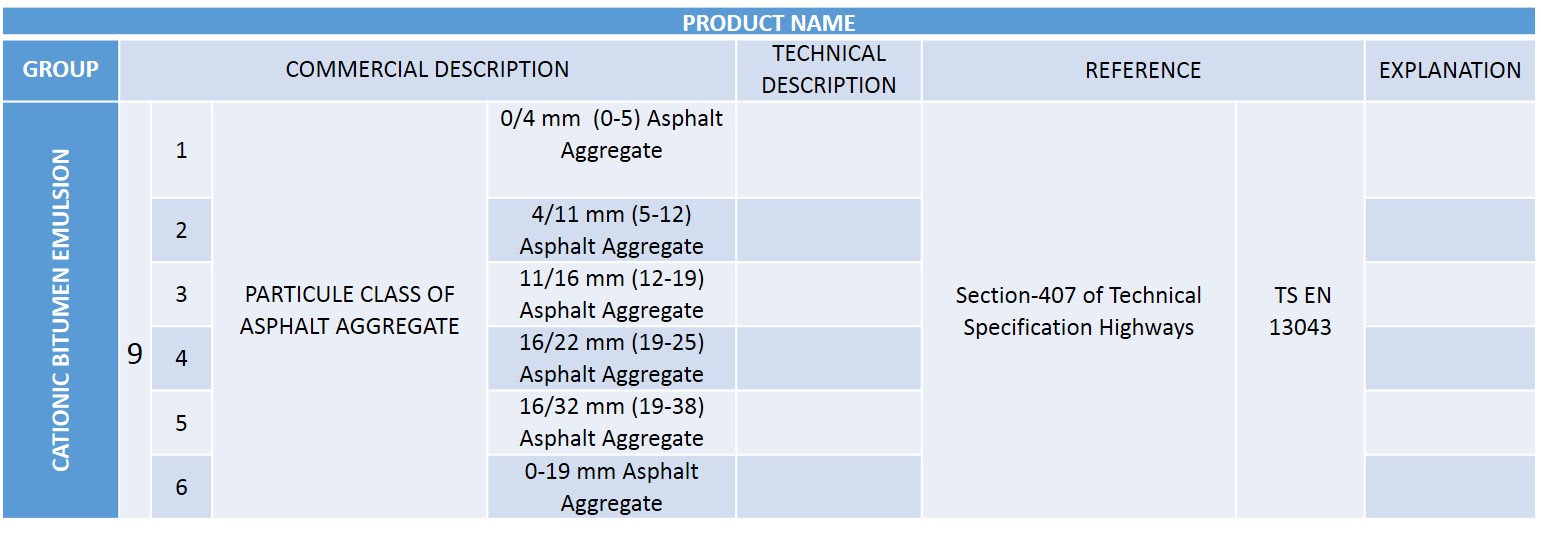

2- ASPHALT AGGREGATES

Our product of asphalt aggregate is produced of high quality by Simge Challenger, special production of E-MAK, in accordance with Technical Specification of Highways and the standard of TS EN 13043 and by means of the system it is delivered directly to our costumer as moisture free and without any quality loss. Asphalt aggregate is produced in particularly five different particule-size distribution:

- 0/4 mm,

- 4/11 mm,

- 11/16 mm,

- 16/22 mm and

- 16/32 mm

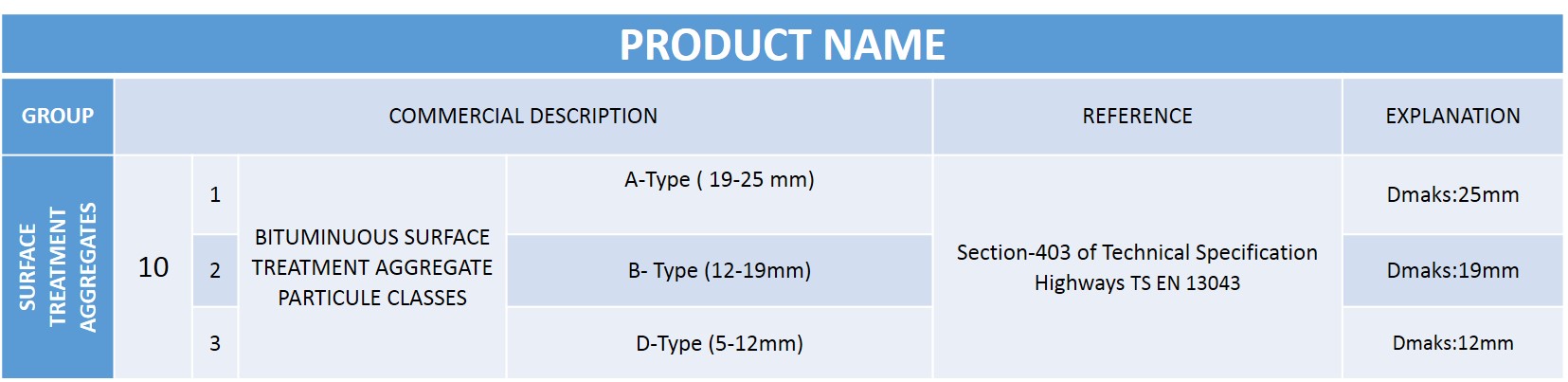

3- SURFACE TREATMENT AGGREGATES

Our products of surface treatment aggregates are produced of high quality by Simge Challenger, special production of E-MAK, in accordance with Section -403 of Technical Specifications of Highways and by means of the system it is delivered directly to our costumer as moisture free and without any quality loss. Surface treatment aggregate is produced in particularly three different particule-size distribution:

- A Type,

- B Type

- C Type

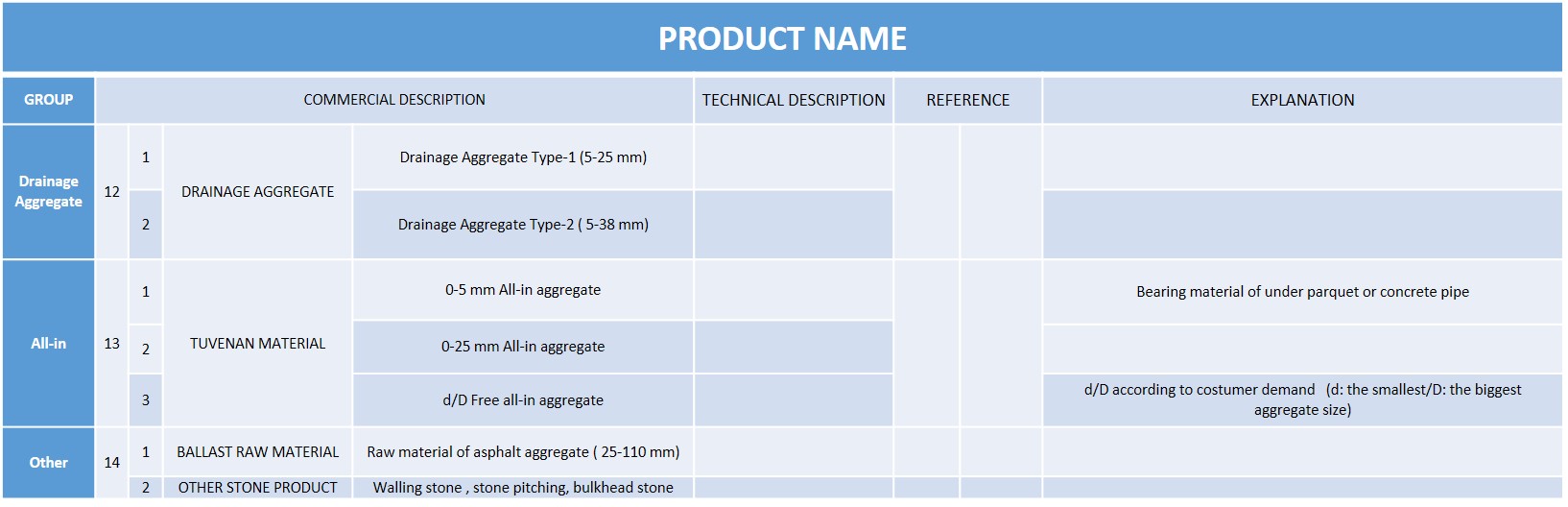

4- OTHER AGGREGATES PRODUCTS:

Two types of drainage aggregate group, all-in ballast material group and other stone products are produced of required quality and physical characteristics by our crushing and screening plants with the purpose of using for construction drainage works and other construction works.

Productions of all-in aggregates are implemented as having feature of bedding materials or proper gradation and characteristics required by Client in accordance with the Standard of TS EN 1610.

E- BITUMINUOUS MATERIAL AND ADHESIVE PRODUCTS

1- MODIFIED BITUMEN

By Modified Bitumen Production Plant in our Körfez Branch, through using special SBS additive materials, modified bitumen is produced of high quality in all performance classes including from PMB 58-28 to PMB 82-22 in accordance with the Section-412 of Technical Specification of Highways and The Standard of TS EN 14023 and submitted to our client as approved by General Directorate of Highways.

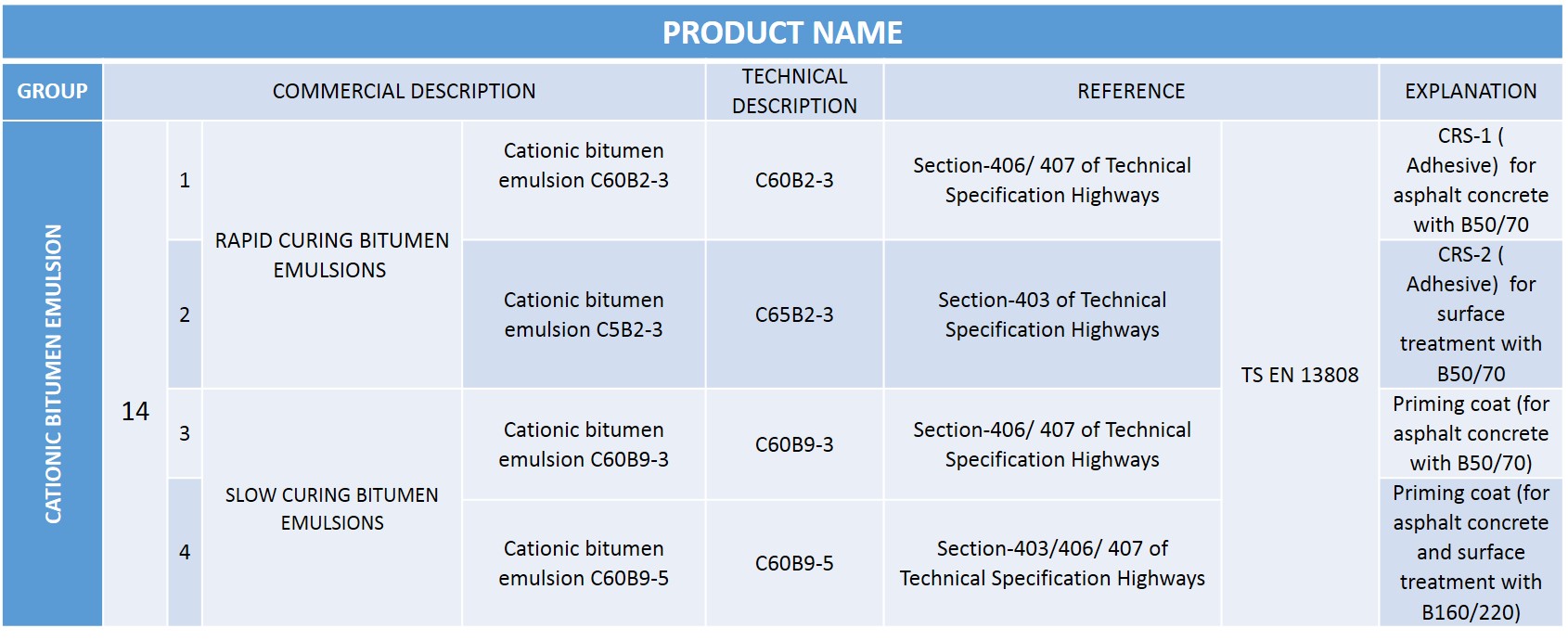

2- CATIONIC BITUMINOUS EMULSION

By our Emulsion Production Plant in Başköy Branch, through using emulgator and special additive materials, bitumen emulsion classes are produced that having feature of high adhesion and delivering great performance as well can be long term stored under proper storage conditions by means of its special recipe, in accordance with the Section-412 of Technical Specification of Highways and the Standard of TS EN 13808.